Surfboard Finishes, Hot Coat or Gloss?

Sand Only Hot Coat, Gloss, Gloss and Polish…What Should You Get?

We have recently had a few people ask us about the different finishes you can have on your surfboard and what they should get. A matter like this really comes down to personal preference, but it is still fairly important as it can change some of the performance characteristics of your board.

We will cover each one here and let you know when you might want one over another.

Hot Coat

A hot coat is always required.The Hotcoat is a layer of resin that is applied on top of the laminated fiberglass. When a board is simply laminated, the fiberglass is completely saturated with resin, but then a good majority of the resin is squeezed out. If too much resin is left on at this stage, the fiberglass will be too brittle and can fracture easily. If not enough resin, than the fiberglass can easily de-laminate from the board.

The Hotcoat more or less fills in the gaps left in the weave of the cloth after lamination. This not only gives you a smooth surface, but helps prevent water from seeping into the board over time.

It is a must-do stage for any surfboard.

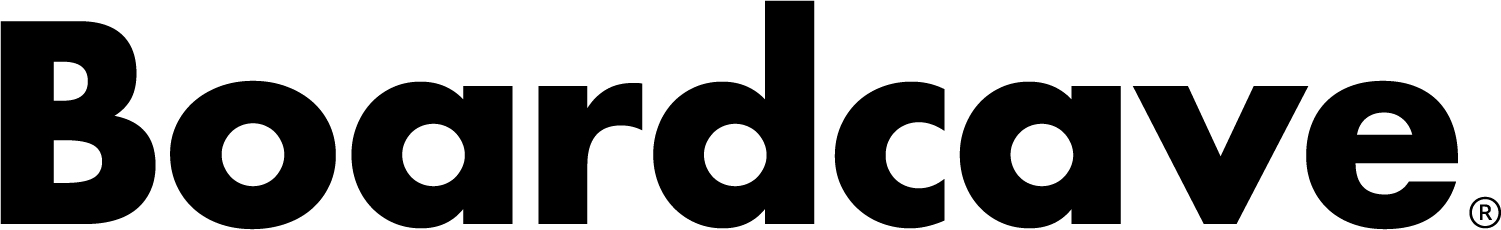

No need for a shiny gloss to make this Flying Turtle by Surf Prescriptions stand out. Leaving just a hotcoat keeps this board light and fast.

Option 1. The Sand Only Hot Coat

The sand only hot coat is the most basic of all the finishes. Usually found on more high performance shortboards, this application allows the weave of the fiberglass to be filled in and helps to prevent that water seeping in as stated above. The advantage of having a sand only hotcoat is that the board can be as light as possible as this is the least amount of resin needed on a finished board.Hotcoat or sanding resin as it is sometimes referred to, has a wax solution added to it allowing it harden up enough to be sanded. Without the wax solution, the resin alone would gum up the sand paper, making it nearly impossible to sand down.

When the hotcoat is applied, the idea is to make sure there is enough resin on the board to ensure the weave left by the lamination is completely filled. The excess resin gets sanded off leaving a board as light as possible while remaining as water tight as possible.

The drawback of a sand only hotcoat is that over time, it can potentially slowly take on water, as well as the board being more fragile in general…more prone to dings breaking right through the fiberglass.

Great for high performance boards, or another style of board where you want as light a finished product as possible, but you can not expect the board to last you as long as you may want if you intend to keep the board for a long period of time.

If you do intend to keep your board for as long as possible, you may want to consider adding a Gloss Coat. The gloss coat can come in two forms: Sanded Gloss, and Polished Gloss.

Option 2. The Gloss Coat Options

A Gloss Coat is yet another layer of resin applied to the board after a hotcoat is applied and sanded down. It is another form of resin also with a wax solution added to give you and extra layer of protection and well as an aesthetically pleasing look.

Gloss Coats are usually found on longboards, alternative surfboards, or retro style of boards. It does add weight to a board, so that is why the majority (not all) of shortboards do not get a gloss coat.

That added weight can come in handy for longboards and some of the retro style boards…helping to keep momentum going down the line, etc. and the extra resin gives and added layer of protection against any dings your board my be prone to. It does cost a little extra to add a gloss coat, but if you care about the longevity of your board, it is a small price to pay.

Remember, there are two ways you can ask for your gloss coat:Sanded Gloss

A sanded gloss coat is exactly what it sounds like. The Gloss is laid, dries, and gets sanded to a high grit. A polish is the same process but when it comes to sanding, it is usually wet sanded and then polished to give you a nice mirror like glossy finish.Some people claim that a sanded gloss is a little faster than a polished gloss due to the slight texture of the finish holding on to a very small layer of water forming a barrier around the board. That small layer/barrier stays with the board allowing friction-less water against water glide.

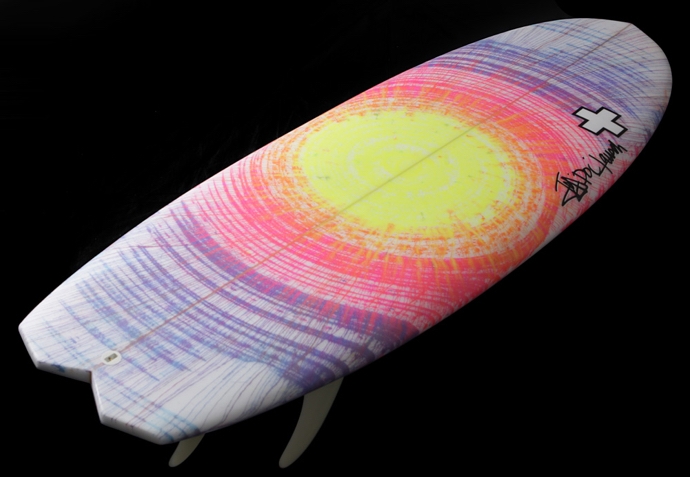

This Wilderness by Album Surfboards brings you the best of both worlds, gloss and polish with a sanded gloss tail dip.

Polished Gloss

A polished gloss (as you can imagine) gives you a nice glossy finish. Great for high end boards with color work, or even wall hangers and collectibles. That doesn’t mean you shouldn’t surf them though, they are built to ride as all boards should be.Apart from the extra layer of resin helping to prevent dings, they also help prevent the water absorption that your board could go through over time. A simple hotcoat on a board does eventually take on water as it is somewhat porous. This is why shortboards, or other boards finished with just a hotcoat do seem to change color and degrade faster than a glossed board.

Keep in mind, all boards will discolor if exposed to sunlight or it’s U.V. rays over time gloss or not. The speed of a sanded gloss and keeping the board from seeing harmful U.V. rays will help support the longevity of your board.

Summary

There is no right or wrong reasons for you to choose one finish over another, but this at least gives you something to consider when ordering your next board. Having trouble deciding on your perfect board? Try our board engine to find that perfect volume.Popular Surfboards

Shop All Surfboards